Garage Safety Tips

Garages and workshops are essential spaces for mechanical work, but they also come with a unique set of hazards. Mechanics and safety personnel are especially vulnerable to chemical exposure, equipment accidents, and other workplace dangers. That’s why strict safety standards exist and why following them can mean the difference between a safe, productive day and a serious injury.

One of the most frequently violated regulations in garage environments is the “Right to Know” standard. This rule ensures employees are fully informed about the chemicals they work with. It requires proper labeling on all chemical containers, a detailed inventory of substances on-site, employee training in chemical safety, and a written plan outlining how the garage will communicate these risks.

Personal protective equipment (PPE) is also essential in garage work. Employers must supply the right gear for each task, from respirators for painting jobs to head protection and hearing protection like earplugs or earmuffs. Additionally, all tools and equipment must be properly maintained. Mechanics should be trained not only in how to use tools, but also in understanding potential hazards.

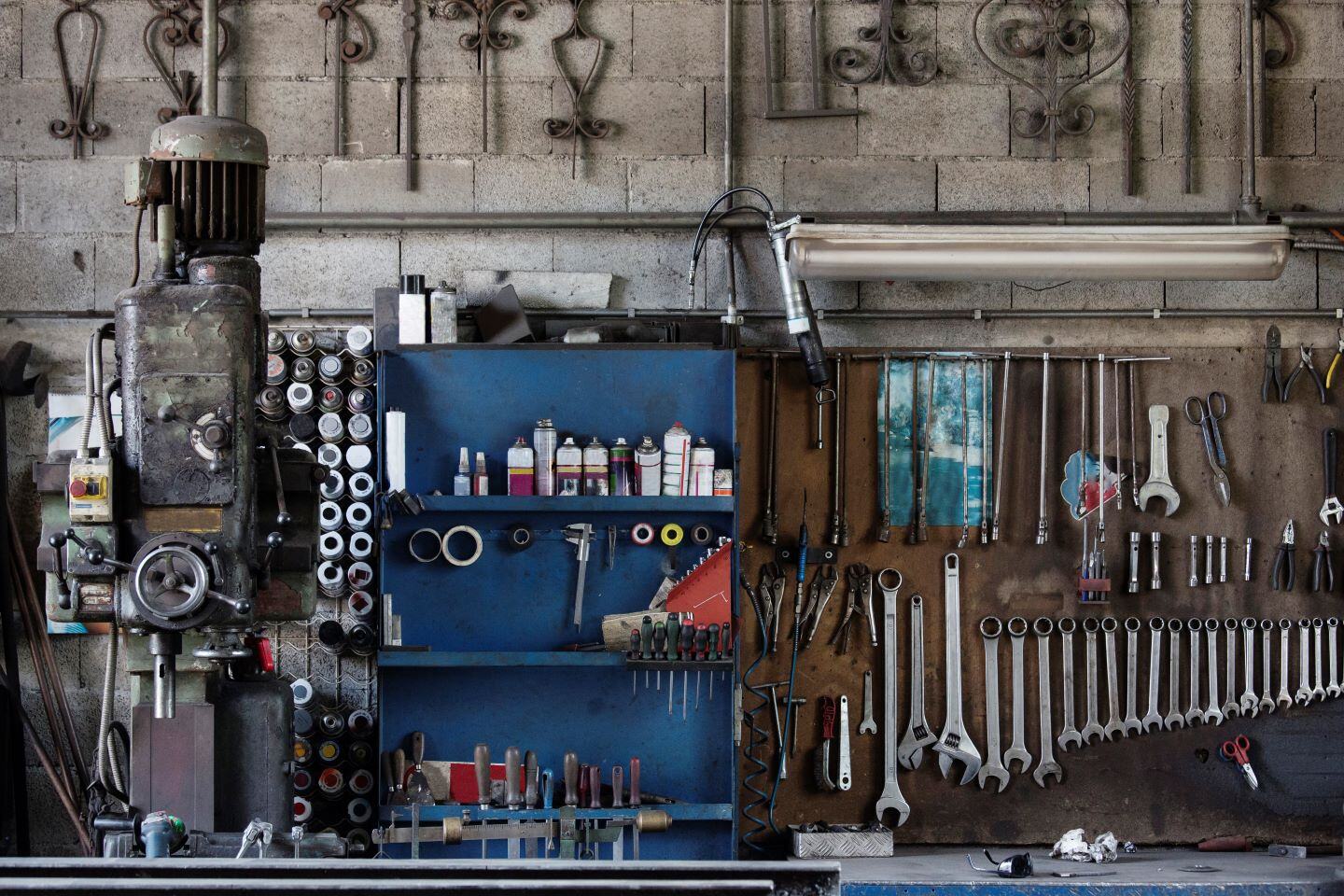

A well-organized shop is also a safer shop. Housekeeping and equipment storage standards are in place to ensure a clutter-free, navigable workspace. Floors should always be kept clear to allow easy movement, and any spills should be cleaned immediately. Tools and parts not in use must be returned to their proper places. Fire extinguishers, eyewash stations, and first aid kits should be easily accessible, and all staff should know where they are located.

The garage layout must also meet specific safety standards. Electrical wiring must comply with code, evacuation plans must be posted, and designated smoking areas must be enforced. Simple practices like turning off equipment and keeping the keys in your pocket while performing maintenance can prevent accidental start-ups and save lives.

Here are a few daily safety tips to help reduce risk:

- Allow engines to cool before beginning work.

- Always wear eye protection.

- Avoid loose clothing or jewelry when working on equipment.

- Set parking brakes, use wheel chocks, and secure bed props.

- Never remove a radiator cap while the system is hot.

- Ensure proper ventilation is in place.

In a familiar setting like a garage, it's easy to let your guard down, but the dangers are very real. That's why it's vital to uphold consistent safety practices and stay vigilant.

Every team member should receive proper training and be aware of the risk control measures linked to their roles. This means understanding not only how to operate machinery safely but also recognizing potential hazards in the environment. By staying educated, keeping equipment in check, and following appropriate protocols, garage staff can greatly minimize risks and foster a safer work environment for all.

Regular safety meetings and drills can reinforce this mindset, ensuring everyone is on the same page. Remember, safety is not just a checklist; it's a daily mindset! So, help ensure everyone is proactive about safety every single day.